Our association is located in Tsubame City, which is in a region roughly in the center of Niigata Prefecture. This region has many companies that focus on metalworking. Ever since our initial establishment in 1964 as the “Japan Exported Kitchen Tools Industry Association”, we have been supporting the industry in various ways through activities such as the stabilization of exports, the development of metalworking technology, developments and test productions of products in new fields with newly developed materials, market research on kitchen tools, the formulation of product safety measures, research on the formation of production region brands, and more.

Location

6856, Higashiota, Tsubame City, Niigata Prefecture 959-1289 [at the Tsubame Chamber of Commerce & Industry]

TEL: 0256-61-5888 FAX: 0256-61-5889

Association Activities

- Training and education, gathering and providing of information, and research studies related to the metal houseware manufacturing industry.

- Creating of structural improvement plans, promoting of production region development projects, training, etc.

- Joint procurement, joint processing, joint sales, joint storage, joint inspections, and joint efforts in the receiving of orders of houseware handled by association members.

- Loaning of business funds to association members and the borrowing of these funds for the association members.

History

| July 1964 | Established as the “Japan Exported Kitchen Tools Industry Association” |

|---|---|

| March 1966 | Reorganized as the “Japan Exported Metal Houseware Industry Association” |

| December 1982 | Reorganized as the “Japan Metal Houseware (with a hyphen after "Houseware" in the Japanese name) Industry Association” |

| August 2000 | Reorganized as the “Japan Metal Houseware Industry Association” |

The Beginnings of Metalworking

Tsubame City, which is located roughly in the center of Niigata Prefecture, has had manufacturing skills from a long time ago, and developed as a metalworking town as the skills improved.

The history of metal product processing began with the manufacturing of Japanese nails around 1698 during the Edo period. Since then, the foundation for the manufacturing of files was established in 1707 and Tsubame City flourished as a metalware production area with the manufacturing of Japanese smoking pipes in 1764, inkwells in 1795, and hand-hammered copperware in 1804. Western food became popular in Japan with cultural enlightenment towards the end of the Meiji period and orders for the production of western metal tableware started coming in from Tokyo. The western metal tableware industry then began with handmade trial productions with the metalworking skills that had been cultivated in Tsubame as its foundation.

Gyokkodou Seisakusyo was also issued with stainless steel sheets by the Japan Stainless Steel Company in October 1945 to fulfill large orders of milkpans, and this set off the production of metal houseware, which was cooking utensils for both commercial and household use. The full-scale manufacturing of stainless steel products began in 1946 when the first stainless steel water boilers in Japan were produced, and this has continued to this day.

Efforts are currently being made in high value-added manufacturing such as those in the processing of new materials such as titanium and magnesium alloys and research and development in new technologies while applying the metalworking technology that has been cultivated throughout its long history.

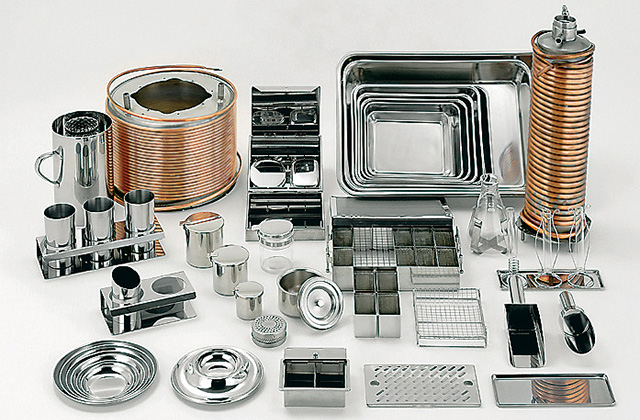

Definitions of “Metal Houseware”

Half-finished iron, steel, copper, copper alloy, titanium, or titanium alloy eating and cooking utensils, and food preparation tools (products processed without the need for molding processing with the use of neither pressing machines, spinning machines, nor welding machines), and their finished products. However, this excludes electrical appliances, products with heating devices or mechanical devices, porcelain enamel ware, cast metal products, zinc-coated products, and hand-processed products.

Like this, there are rigid definitions, and products for daily living such as kettles, pots, frying pans, bowls, and strainers also fall under “Metal Houseware”.

Stainless Steel Products

As a production region for western metal tableware, it has been improving its stainless steel processing technology. Various products including pots and other kitchen tools are being manufactured while taking advantage of their characteristics such as resistance to corrosion and excellent heat retention capabilities.

The polishing techniques here are also renowned for their amazing finishing work on stainless steel surfaces.

Ironware

Iron is used in many cooking utensils that are exposed to high temperatures such as woks because of its excellent thermal conduction properties and resistance to high temperatures. Iron can be supplemented when preparing food with it, and it is very durable.

Copperware

Since the latter part of the Edo period, Tsubame City has been a production area of hand-hammered copperware, which is formed while the copper is being pounded. Copper is a favorite material for tools used by professionals due to its antiseptic, antibacterial, and excellent thermal conduction properties.

Cutleries

Kitchen knives are essential for preparing food. Once the technology for manufacturing stainless steel was established, so was the fabrication process where parts of sheet materials are punched out into the shapes of kitchen knives so that they could be mass-produced as knives known as “nukihamono”. Affiliated with the association include Tsubame and Sanjo (Niigata Prefecture), and Seki (Gifu Prefecture), which are among the top production areas of nukihamono in the country.

Western Metal Tableware

Tsubame City is famous for being a major production area. In addition to its processing technology, the beautiful designs of the products it offers are also world-class. They bring a sense of brilliance to the table and make meals more pleasant.

Other Fields

The metalworking technology that has been cultivated throughout the history of manufacturing is now advancing into all kinds of fields. Its possibilities are expanding to include the medical field, golf heads, automotive parts, and more.

Our association is located in Tsubame City, which is in a region roughly in the center of Niigata Prefecture. This region has many companies that focus on metalworking. Ever since our initial establishment in 1964 as the “Japan Exported Kitchen Tools Industry Association”, we have been supporting the industry in various ways through activities such as the stabilization of exports, the development of metalworking technology, developments and test productions of products in new fields with newly developed materials, market research on kitchen tools, the formulation of product safety measures, research on the formation of production region brands, and more.

Location

6856, Higashiota, Tsubame City, Niigata Prefecture 959-1289 [at the Tsubame Chamber of Commerce & Industry]

TEL: 0256-61-5888 FAX: 0256-61-5889

Association Activities

- Training and education, gathering and providing of information, and research studies related to the metal houseware manufacturing industry.

- Creating of structural improvement plans, promoting of production region development projects, training, etc.

- Joint procurement, joint processing, joint sales, joint storage, joint inspections, and joint efforts in the receiving of orders of houseware handled by association members.

- Loaning of business funds to association members and the borrowing of these funds for the association members.

History

| July 1964 | Established as the “Japan Exported Kitchen Tools Industry Association” |

|---|---|

| March 1966 | Reorganized as the “Japan Exported Metal Houseware Industry Association” |

| December 1982 | Reorganized as the “Japan Metal Houseware (with a hyphen after "Houseware" in the Japanese name) Industry Association” |

| August 2000 | Reorganized as the “Japan Metal Houseware Industry Association” |

The Beginnings of Metalworking

Tsubame City, which is located roughly in the center of Niigata Prefecture, has had manufacturing skills from a long time ago, and developed as a metalworking town as the skills improved.

The history of metal product processing began with the manufacturing of Japanese nails around 1698 during the Edo period. Since then, the foundation for the manufacturing of files was established in 1707 and Tsubame City flourished as a metalware production area with the manufacturing of Japanese smoking pipes in 1764, inkwells in 1795, and hand-hammered copperware in 1804. Western food became popular in Japan with cultural enlightenment towards the end of the Meiji period and orders for the production of western metal tableware started coming in from Tokyo. The western metal tableware industry then began with handmade trial productions with the metalworking skills that had been cultivated in Tsubame as its foundation.

Gyokkodou Seisakusyo was also issued with stainless steel sheets by the Japan Stainless Steel Company in October 1945 to fulfill large orders of milkpans, and this set off the production of metal houseware, which was cooking utensils for both commercial and household use. The full-scale manufacturing of stainless steel products began in 1946 when the first stainless steel water boilers in Japan were produced, and this has continued to this day.

Efforts are currently being made in high value-added manufacturing such as those in the processing of new materials such as titanium and magnesium alloys and research and development in new technologies while applying the metalworking technology that has been cultivated throughout its long history.

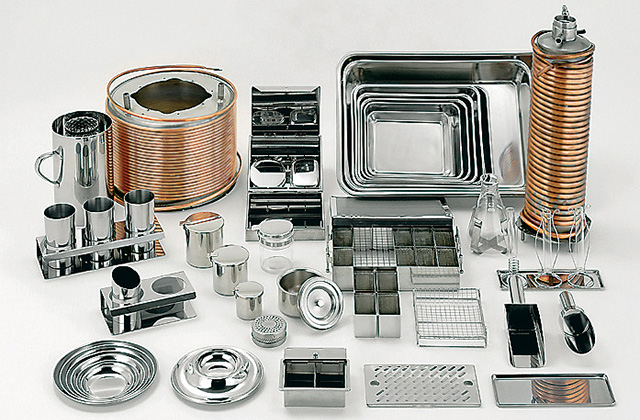

Definitions of “Metal Houseware”

Half-finished iron, steel, copper, copper alloy, titanium, or titanium alloy eating and cooking utensils, and food preparation tools (products processed without the need for molding processing with the use of neither pressing machines, spinning machines, nor welding machines), and their finished products. However, this excludes electrical appliances, products with heating devices or mechanical devices, porcelain enamel ware, cast metal products, zinc-coated products, and hand-processed products.

Like this, there are rigid definitions, and products for daily living such as kettles, pots, frying pans, bowls, and strainers also fall under “Metal Houseware”.

Stainless Steel Products

As a production region for western metal tableware, it has been improving its stainless steel processing technology. Various products including pots and other kitchen tools are being manufactured while taking advantage of their characteristics such as resistance to corrosion and excellent heat retention capabilities.

The polishing techniques here are also renowned for their amazing finishing work on stainless steel surfaces.

Ironware

Iron is used in many cooking utensils that are exposed to high temperatures such as woks because of its excellent thermal conduction properties and resistance to high temperatures. Iron can be supplemented when preparing food with it, and it is very durable.

Copperware

Since the latter part of the Edo period, Tsubame City has been a production area of hand-hammered copperware, which is formed while the copper is being pounded. Copper is a favorite material for tools used by professionals due to its antiseptic, antibacterial, and excellent thermal conduction properties.

Cutleries

Kitchen knives are essential for preparing food. Once the technology for manufacturing stainless steel was established, so was the fabrication process where parts of sheet materials are punched out into the shapes of kitchen knives so that they could be mass-produced as knives known as “nukihamono”. Affiliated with the association include Tsubame and Sanjo (Niigata Prefecture), and Seki (Gifu Prefecture), which are among the top production areas of nukihamono in the country.

Western Metal Tableware

Tsubame City is famous for being a major production area. In addition to its processing technology, the beautiful designs of the products it offers are also world-class. They bring a sense of brilliance to the table and make meals more pleasant.

Other Fields

The metalworking technology that has been cultivated throughout the history of manufacturing is now advancing into all kinds of fields. Its possibilities are expanding to include the medical field, golf heads, automotive parts, and more.